A spray dryer is a type of industrial machinery used to turn liquids into powders or granules. This whole thing is done in a single step. The liquid is atomized into tiny droplets, and the moisture is subsequently removed by drying the droplets in a hot air stream. The end result is a fluid powder that is simple to carry and package. In comparison to other drying techniques, spray drying is a common process in the food, pharmaceutical, and chemical sectors because of its high efficiency, adaptability, and consistent product quality.

In this article, we’ll take a look at:

So, let’s start right at the beginning: a brief history of spray dryers!

A French engineer by the name of Alexis Millardet first employed spray drying in the 19th century to create dried wine yeast for the wine business. But the procedure wasn't commonly used until the middle of the 20th century. In the 1930s, the first spray dryer for use in the industry was created.

Nozzle atomizers were employed in the earliest known spray dryers before rotary atomizers were developed decades later. Very little commercial use of the technology was realized until the 1920s because of the relatively straightforward designs of the first spray dryers and the practical challenges of operating them continually. But since then, this technology has advanced and changed throughout time to fit a wide variety of industries.

Now, let’s discuss the working principle of a spray dryer. The most common spray dryers consist of several key components:

and a collection system.

Here’s how they work in harmony:

| Feed Preparation | To create the liquid feed, the components are combined, the viscosity is changed, and the mixture is homogenized. |

| Atomization | First, the liquid to be dried is pumped into the spray nozzle or a spinning disk, where it is atomized into fine droplets. |

| Dehydrating | The droplets are then introduced into the drying chamber, where they are rapidly dried by the hot air stream. To achieve the correct particle size, morphology, and residual moisture content, the hot air's temperature and flow rate are carefully regulated. |

| Collection System | The dried powder is then collected by the collection system (typically using centrifugal forces with a cyclone or a bag filter) and may be packaged or further processed. |

So, as you can see, the key to the spray drying process is the rapid evaporation of the liquid droplets in the hot air stream.

The drying rate is influenced by several factors, including:

You can choose to control these factors to produce a consistent, high-quality product.

There are several types of spray dryers available. The type of spray dryer used will depend on the properties of the liquid feed, the desired final product, and the production capacity required.

The rotary atomizer atomizes the liquid supply into droplets using a spinning wheel. This style of spray dryer can produce a large amount of product and is the most flexible atomization system applicable to a wide range of feed materials and can be used on very high viscosity applications. Rotary atomizers can be designed to handle abrasive slurries by use of wheels with ceramic inserts.

This kind of drier atomizes the liquid into droplets using a high-pressure pump (up to 300 bar) to create a consistent, homogenous powder. Pressure nozzle systems can produce powder with a consistent and narrow particle size which is often required to give good flow properties and consistent bulk density. The food and dairy sectors are the ones that use these dryers the most frequently.

Two fluid nozzles use a gas under pressure (4 to 10 bar) to atomize the liquid. The most frequently used gases are compressed air or steam. The two fluids Gas and liquid feed meet in a small chamber where the high velocity gas breaks up the liquid into fine droplets. This type of nozzle is often used for pilot dryers.

Spray dryers are often combined with fluidized beds. The fluid beds can be integrated into the bottom of the spray drying cone with the fluidising air exhausting together with the spray chamber air. Also external fluid bed processors can follow the spray chamber to remove small quantities of moisture and or cool the product. The external fluid beds are often vibrated to help with fluidisation of the product. These 2 stage and 3 stage drying systems are most often used to produce agglomerated material and eliminate dust.

These dryers are intended for uses where the product is susceptible to oxidation or the solvent is not water but an organic liquid which has a flammable vapour. The drying procedure is carried out in a closed loop, using nitrogen as the drying medium instead of air to exclude oxygen from the drying process. A cooler/condenser is used in the closed loop to recover the sovent.

One of the main advantages of spray drying is its ability to produce a free-flowing powder that is easy to handle and transport in one processing stage. Spray drying itself is not the lowest cost method of production but it can produce a powder directly from a liquid in one step. Most other methods would use multiple steps (ie dewatering and fluid bed or flash drying) For this reason when operating small production plants or pilot systems a spray dryer usually means less capital cost even though the operating cost may be higher.

However, there are many other advantages to using a spray drying method.

One of the most significant benefits of spray drying is its ability to produce a powder from a liquid feed. Spray drying is thus a cost-effective way for creating a wide range of products such as food ingredients, pharmaceuticals, chemicals, and cosmetics.

Because the approach is so widely used, you can choose high-quality, dependable components for optimal service life and availability. Often spray drying is used when developing new products as it can be applied with a relatively short development programme.

Particles produced by spray drying are distinguished by their uniform particle size and stability. This higher level of product quality is crucial in a variety of industries, including food, medicines, and cosmetics. The homogeneous particle size of spray-dried powders makes them excellent for use in the manufacture of these products, as they are easier to process and have better flow properties.

End-to-end traceability in accordance with current food standards and laws is also enabled via automated process control.

The potency and efficacy of active compounds must be preserved in industries such as pharmaceuticals and biotechnology. Spray drying preserves these active components, making it a suitable method for manufacturing high-quality pharmaceuticals and biopharmaceuticals.

Another benefit of spray drying is its customization. This procedure is suitable for a wide range of liquids and suspensions, making it an excellent way for drying a wide range of items. Spray drying's adaptability enables the creation of a diverse spectrum of powders, including food additives, pharmaceuticals, chemicals, and cosmetics.

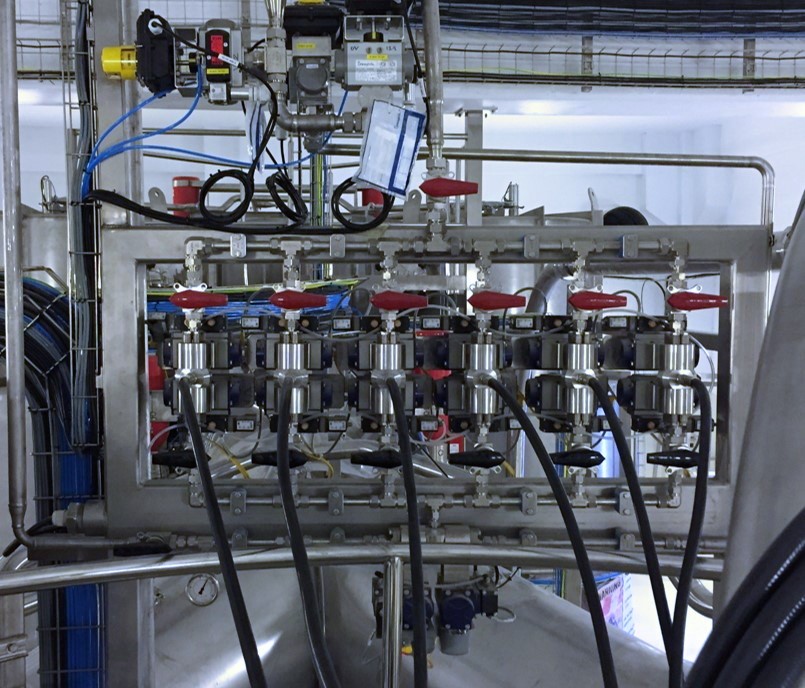

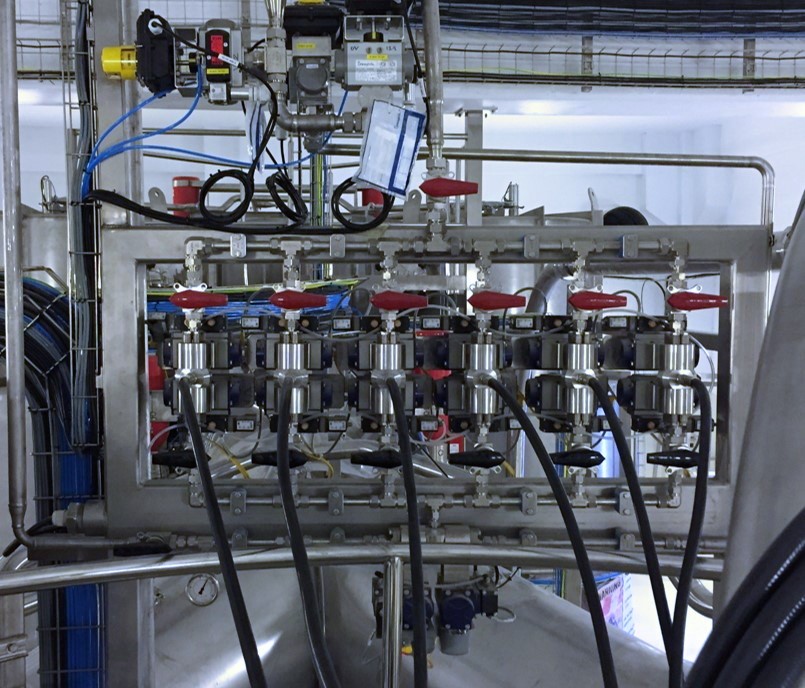

Spray drying can also help to reduce contaminants like bacteria and other microbes. This is especially critical in industries such as food and pharmaceuticals, where the presence of contaminants can lead to the degradation of product quality. Spray dryers most often supplied with CIP (Clean In Place) systems and designed with smooth interior surfaces for easy cleaning.

The advantages of spray drying should already tell you how versatile the solution is for a wide range of industries. So, let’s take a look at the industries that use them.

The food business is one of the largest purchasers of spray drying technology. It is often used to make instant coffee, tea, milk powders, egg products, infant formula, flavours and other food ingredients. Spray drying preserves the flavour, aroma, and color of the food while minimizing bacteria and other contaminants. The process's great speed and efficiency result in a cost-effective technique for generating huge amounts of food ingredients.

As we mentioned earlier, the pharmaceutical industry is also a large consumer of spray drying technology. These industries use it to create powders, granules, and tablets, as well as to encapsulate active substances. The consistent particle size and stability of spray-dried powders make them excellent for use in the production of medicinal products.

Furthermore, the technique preserves the strength and usefulness of the active components, making it a suitable method for producing high-quality pharmaceutical goods.

Spray drying technology is also widely used in the chemical industry. This method is used to create catalysts, pigments, detergents, and other chemical products. Spray drying is also used in the drying of solvents and other chemical solutions in this business. Spray-dried powders are suited for usage as catalysts, pigments, and other chemical products due to their uniform particle size and stability.

The agricultural industry benefits a lot from spray drying tech. This method is used to make animal feed, fertilizer, and pesticides. Because of the high speed and effectiveness of spray drying, it is a cost-effective approach for creating large numbers of these items. Furthermore, the consistent particle size and stability of spray-dried powders make them perfect for usage as animal feed, fertilizer, and pesticide products.

The biotechnology industry is another large consumer of spray drying technology. Creating recombinant proteins, vaccines, and other biopharmaceuticals became much easier once we introduced spray drying in this industry. The potency and efficacy of active chemicals must be preserved in this industry, and spray drying enables for the manufacturing of high-quality biopharmaceuticals.

The environmental industry uses spray drying technology by processing the treatment of wastewater, solid waste, and air pollution. The efficiency and versatility of spray drying make it an ideal method for treating these types of waste products.

You may have already guessed that the cosmetic industry also uses spray drying technology since many products in this industry involves particles. Thus, this type of process is used for the production of cosmetic powders and other personal care products. However, rather than spray drying, we use a spray cooling process because the products used for skincare are usually fats and melt at a low temperature. In this case, the materials are melted to form a liquid and then fed to the atomization system as a molten liquid. The spray is discharged into a cold air stream and solidifies into solid droplets forming a dry powder which is easy to handle.

A growing market for spray drying is the production of powder for the production of cathode and anode materials for EV battery production. This is a new field requiring new forms of atomization and drying to produce materials with a high surface area to give the best battery performance.

No tech is without disadvantages. Spray drying technology is no exception. Here are some disadvantages associated with spray drying:

| Limited feed viscosity | Typically, only feedstocks with a viscosity lower than 500 centipoises can be dried using spray technology. This means that it is necessary to dry at relatively low solids in the feed material. Sometimes the feed must be diluted to achieve the correct viscosity. Other methods of drying can handle much higher solids concentrations and so reduce the size of the dryer. |

| High Capital Cost | It’s an expensive tech to purchase and operate because of the high evaporation rate in relation to other systems. |

| High energy consumption | The heating of the air stream and atomization of the feed during spray drying consumes a lot of energy. Especially for large-scale operations, spray drying may be expensive due to its high energy usage. |

| Operational Safety | Many of the materials produced as dry powders are explosive and or flammable. Spray dryer systems are provided with explosion protection systems and fire safety systems design to safely eliminate any danger of deflagration. These are some of the most important parts of the equipment design. |

You’ve read about the disadvantages of spray dryers. But despite these limitations, the return on investment in spray drying tech is way too profitable to pass on. Plus, in some cases, there’s little to no other alternative to this tech. Adding to this is the fact that since spray drying is so widely available, it is developing at a very fast rate where most of these disadvantages are mitigated by newer innovations in this field to a large enough level.

To continue with our above argument, if you buy your equipment from the right sources, your installations will have the unparalleled cost-benefit that spray dryers are famous for.

Have a look at Dedert’s innovative spray drying technology. The revolutionary, patented high-speed rotary atomizer serves as the foundation for Dedert's new line of spray dryers. The innovative rotary design, which is based on magnetic bearing technology, offers unmatched flexibility for the most demanding applications by doing away with the requirement for high-maintenance gear drives, bearings, shafts, oil lubrication, and cooling systems.

What’s more, is that they are immediately compatible with existing installations on top of being easy to maintain and service. So this is where you can recoup a large portion of your investment quite efficiently.

In conclusion, spray drying is now a ‘household’ name in many industries. It has various benefits over other drying techniques. It may have its complexity and high level of technical skill requirement, but the benefits far outweigh its quirks. However, as with any industry, you may need to thoroughly weigh the advantages over the disadvantages of spray drying and see if it suits your application.

In most cases, you’ll find no other cost-efficient alternative for a spray dryer. However, there are some applications where a ring dryer or a roto flash dryer, may be more appropriate than a spray dryer. Saving energy is necessary for a dry product producer to remain competitive.

To dry an atomized liquid into a powder, the usual spray drying method used today uses air heated to 400° Fahrenheit or about 200° celsius. When delicate, flammable liquid constituents are exposed to high temperatures, molecular degradation occurs that adversely affects the powder's solubility, stability, and flavor character.

A 2018 study revealed that spray-drying outperforms freeze-drying in terms of effectiveness. The aspects considered as the key factors were solubility, hygroscopicity, moisture content, water activity, flowability, and glass transition temperature.

Although a spray dryer may dry a wide variety of products, not all materials are suited for spray drying. Some examples of such products are gels (highly viscous products may not atomize well, leading to clogging of the spray nozzle), foods with high sugar or salt content, products with high heat sensitivity (some vitamins and enzymes), and pastes (same problem as gels) and highly reactive products.

©2024 Dedert Corporation. All Rights Reserved.