Some of the most used applications for synthetic silica are toothpaste and car tires. However, synthetic silica is used in a wide variety of industries and is formulated in numerous ways for both industrial and consumer applications. Generally, silicas have very small particles that are easy to dry. Their particles do not adhere or bind to each other easily. Silicas can be engineered to have very specific properties, thus making them useful for a variety of applications within many industries.

Dedert has three different drying technologies best suited to dry silica:

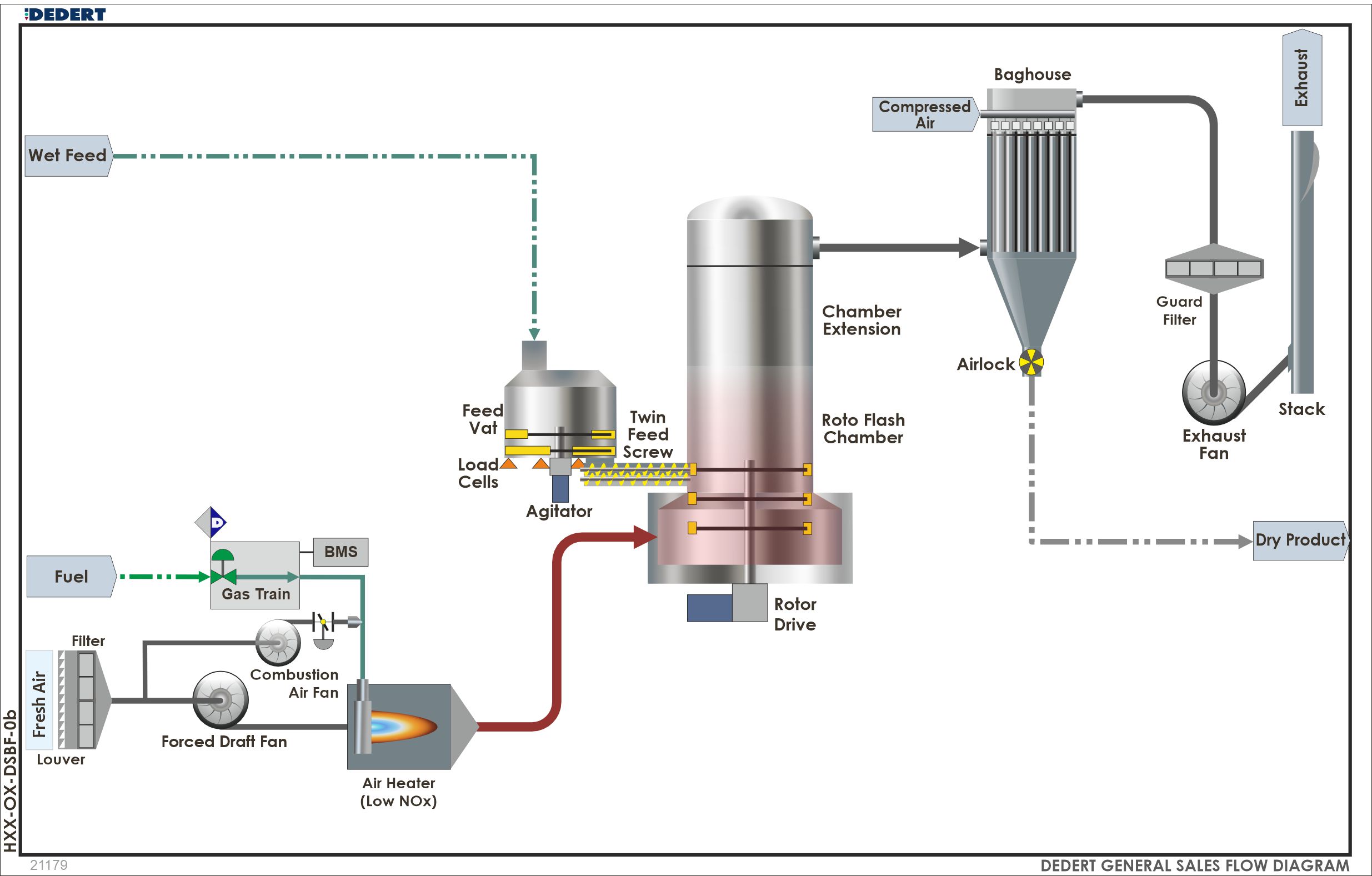

However, Dedert’s Roto-Flash dryer is the most frequently used technology for drying silica. The drying takes place in a cylindrical vertically mounted drying chamber. The rotor-beater assembly provides sufficient force to disperse and break down the wet feed material for drying. A primary advantage of Dedert’s Roto-Flash dryer is that it can dry thicker and pastier materials like wet cakes and slurries. The air residence time is only a few seconds, making the Roto-Flash cost effective in terms of CAPEX and OPEX. The process results in a very fine powder directly from the feed material, without the need to pre-mix with already dried product. The Roto-Flash can break down agglomerates and create very fine particles. This is beneficial for the use of silica to produce a fine particle size distribution used in paints and coatings.

©2025 Dedert Corporation. All Rights Reserved.