For production of fast charging and high-capacity energy batteries, the automotive industry requires exceptionally fine lithium powder.

The powders for lithium-based batteries are made using spray dryers where the electrode materials are mixed into a liquid slurry and then atomized to produce a cloud of droplets in a large chamber where hot air is introduced to drive off the water as vapor and leave behind fine particles which are collected in cyclones or a filter.

Depending on the atomizing technology, we can produce particles of various sizes, more specifically 5-10 microns particle size.

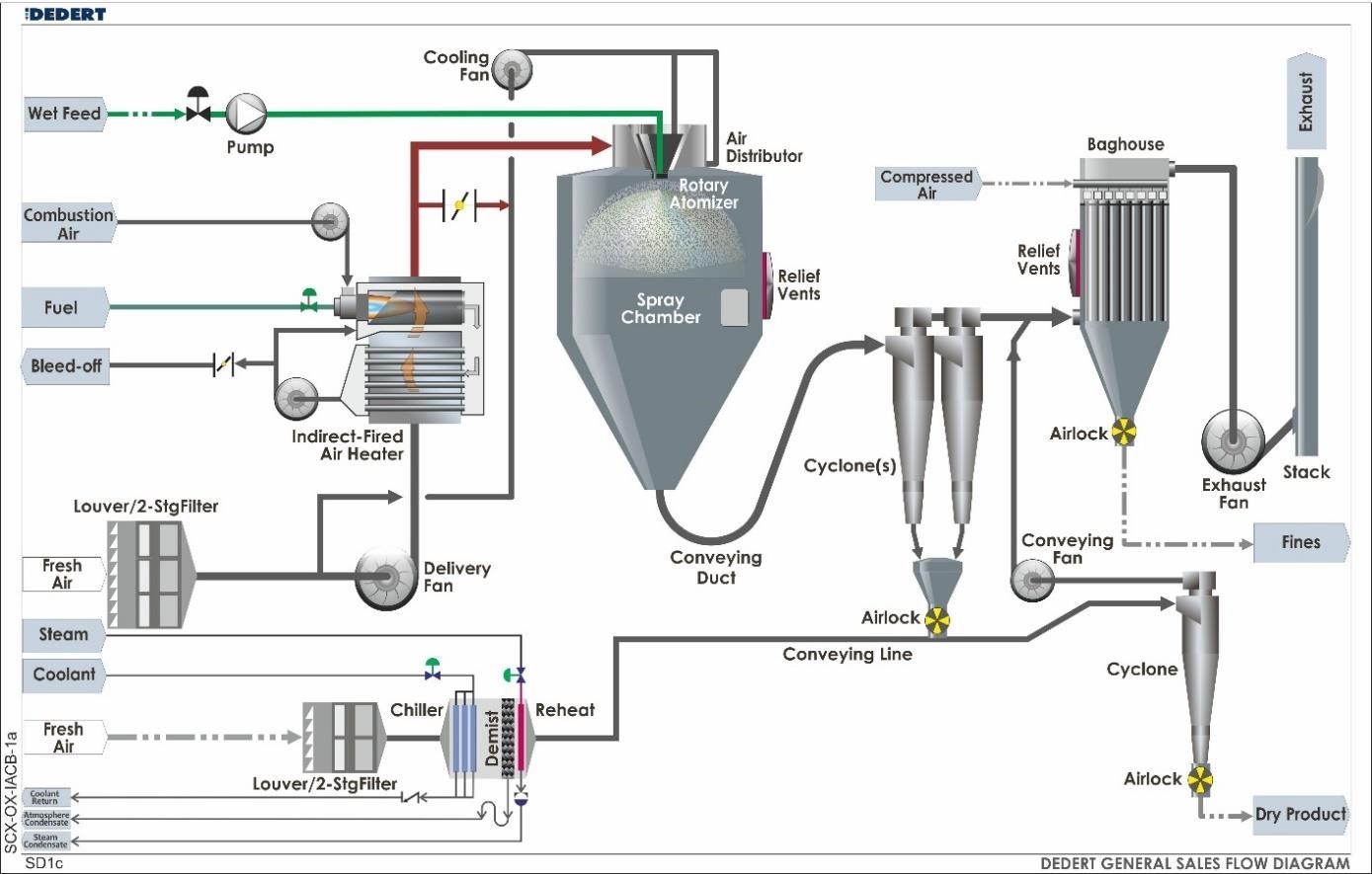

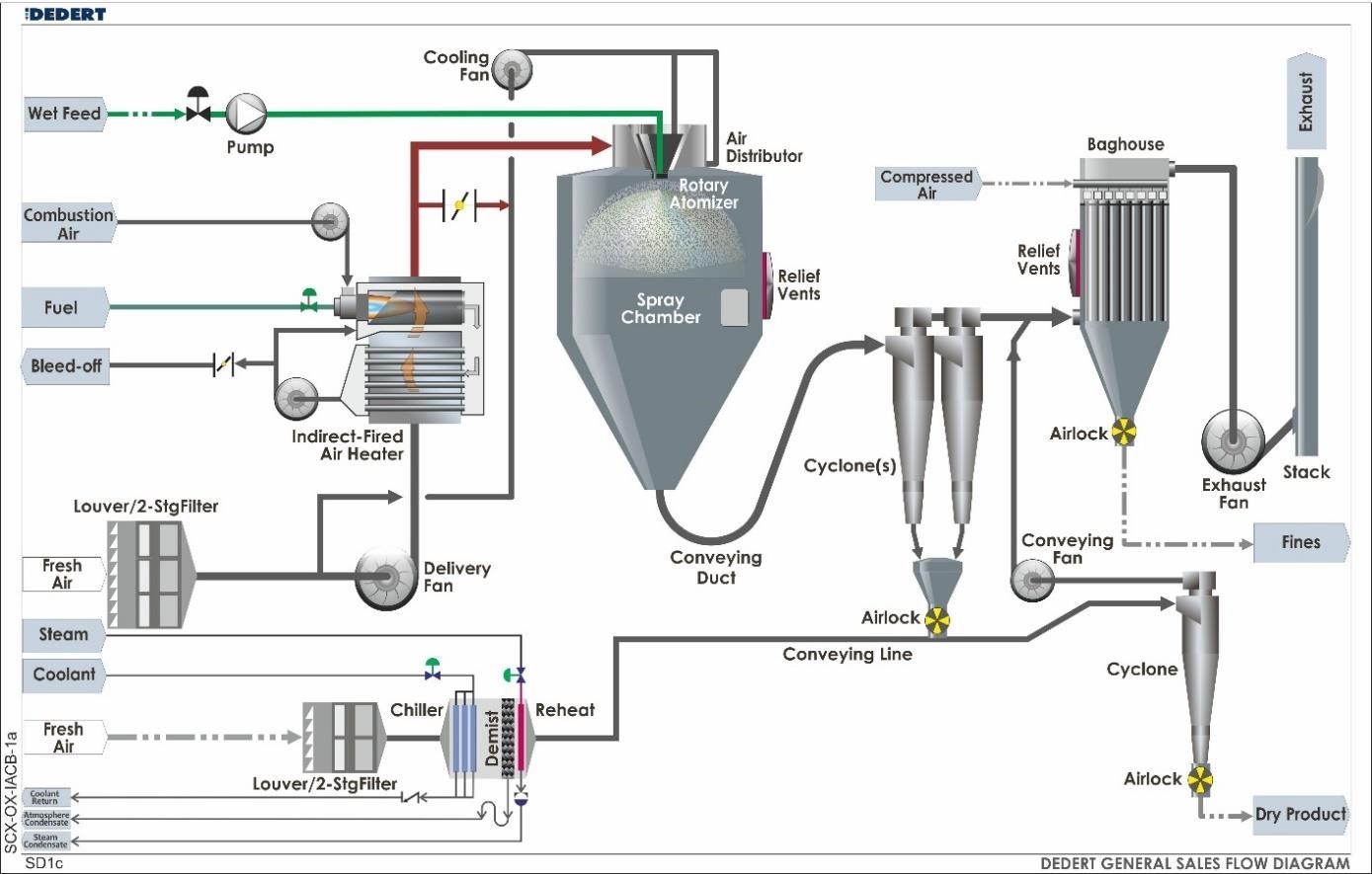

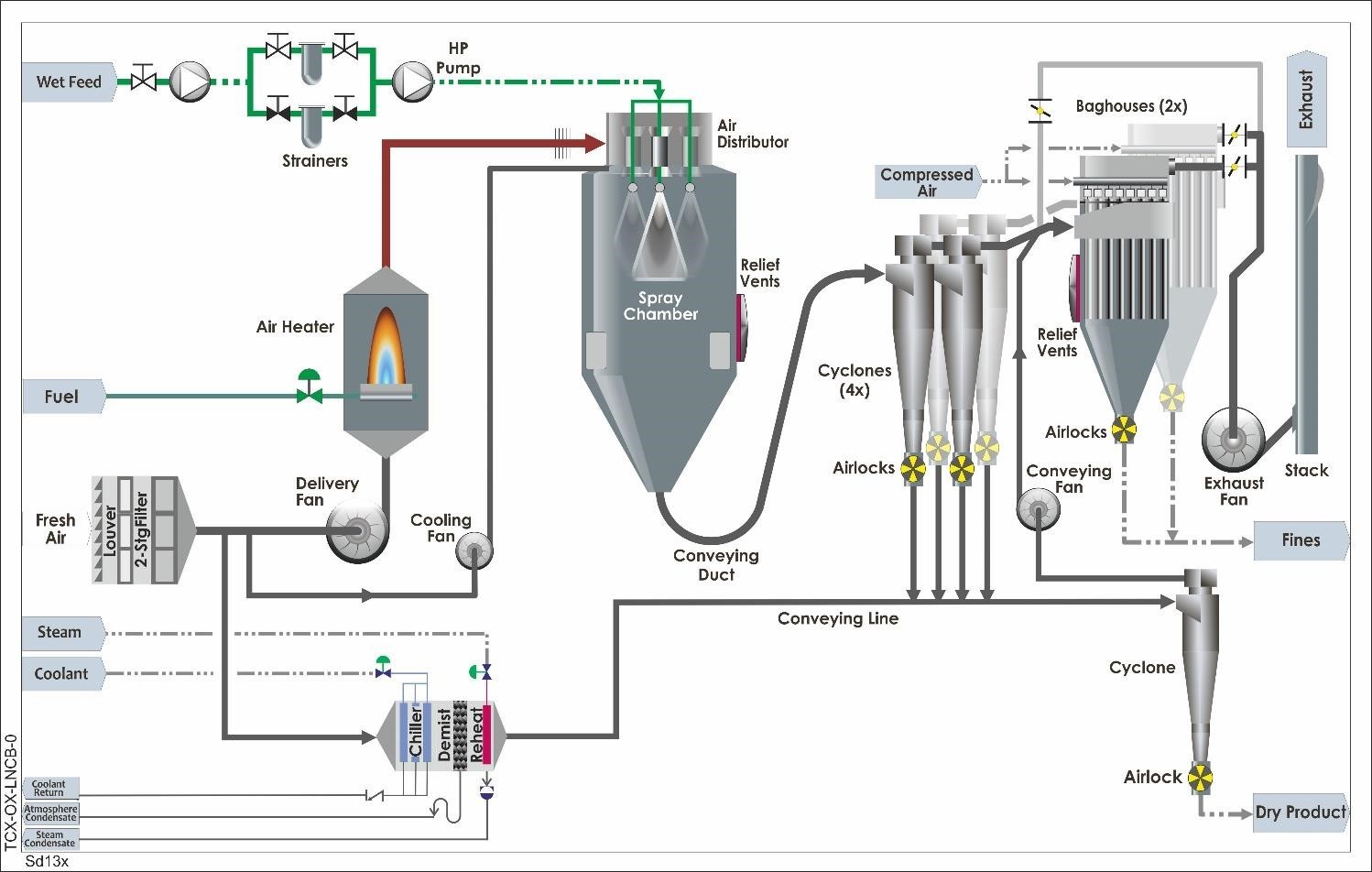

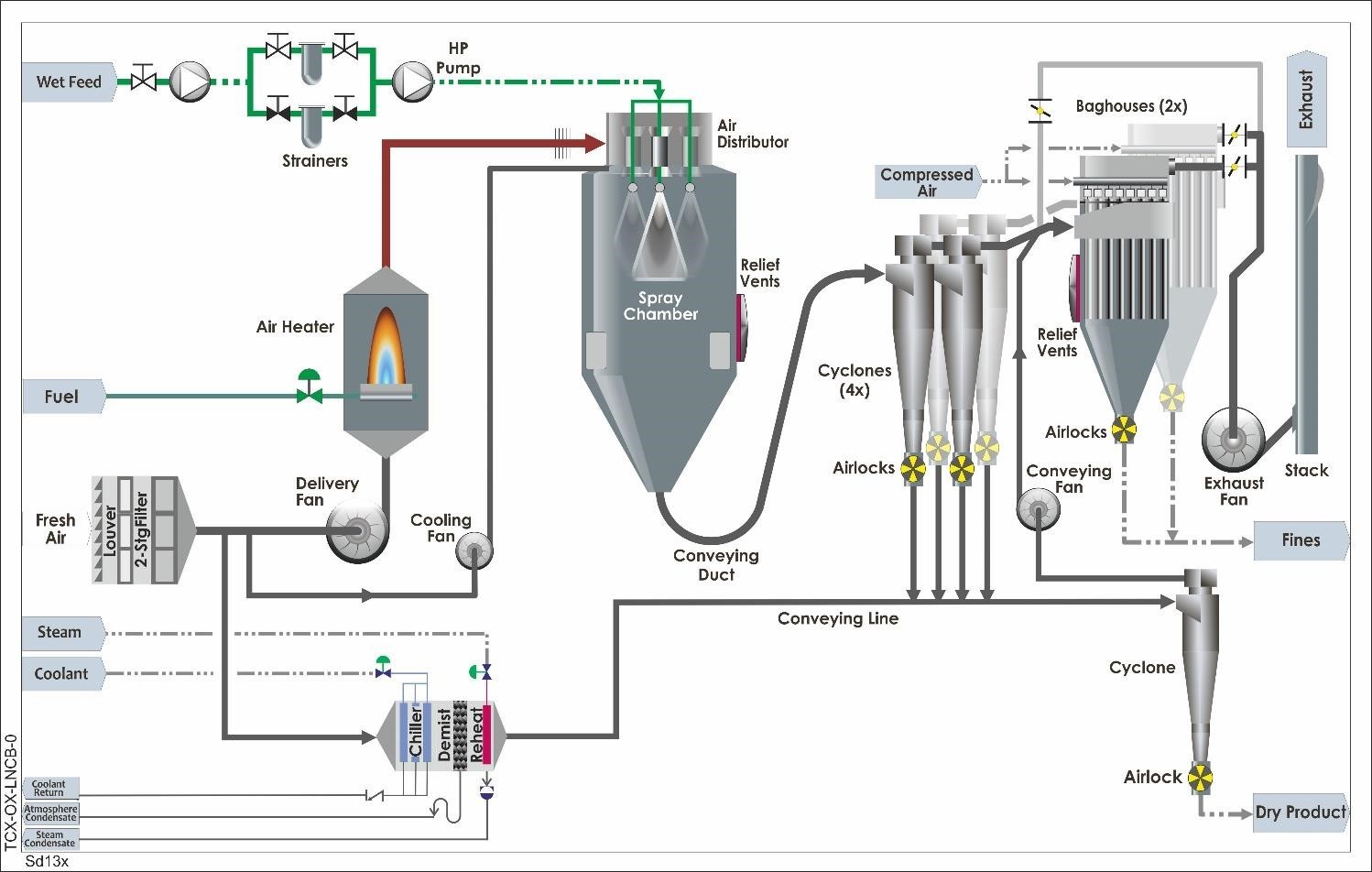

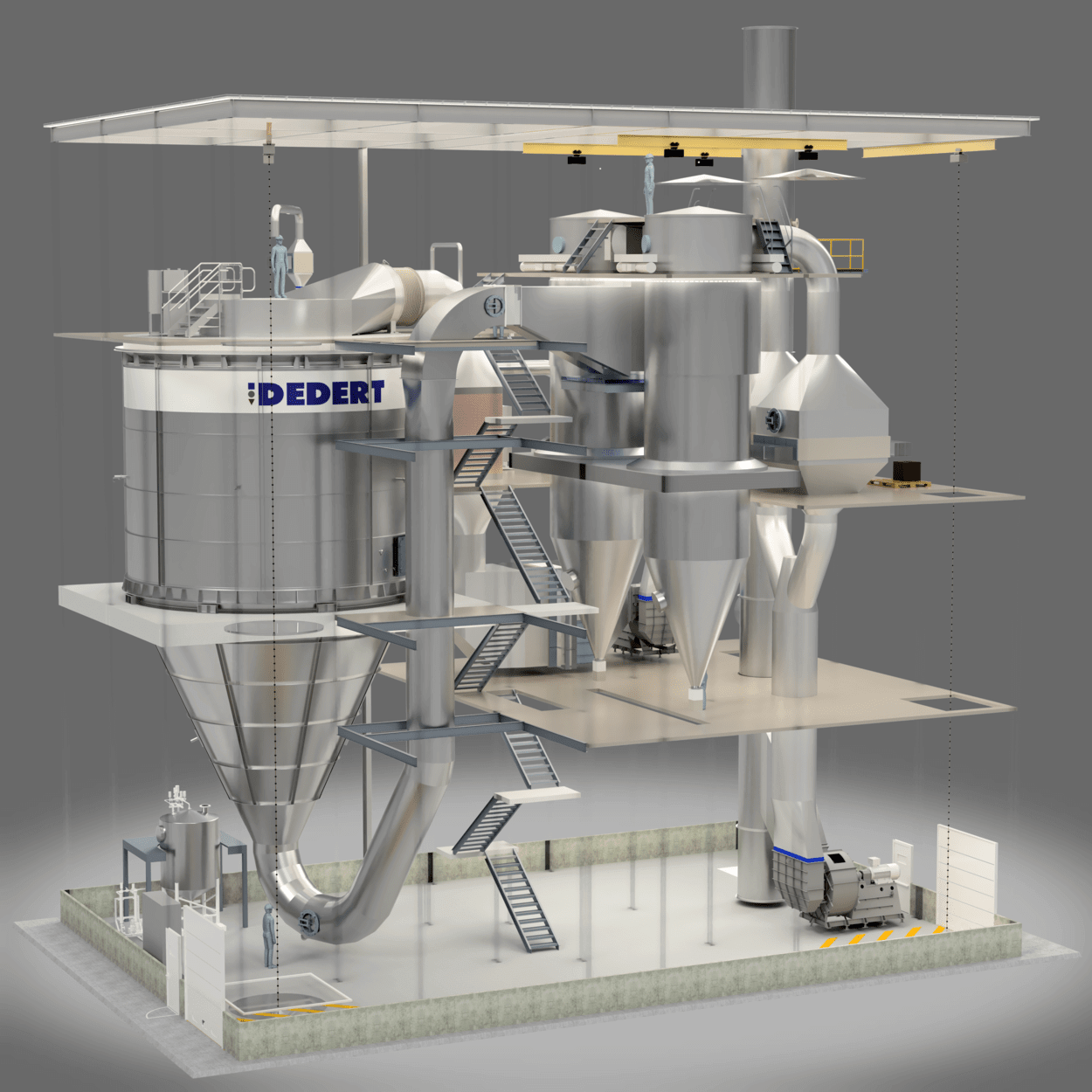

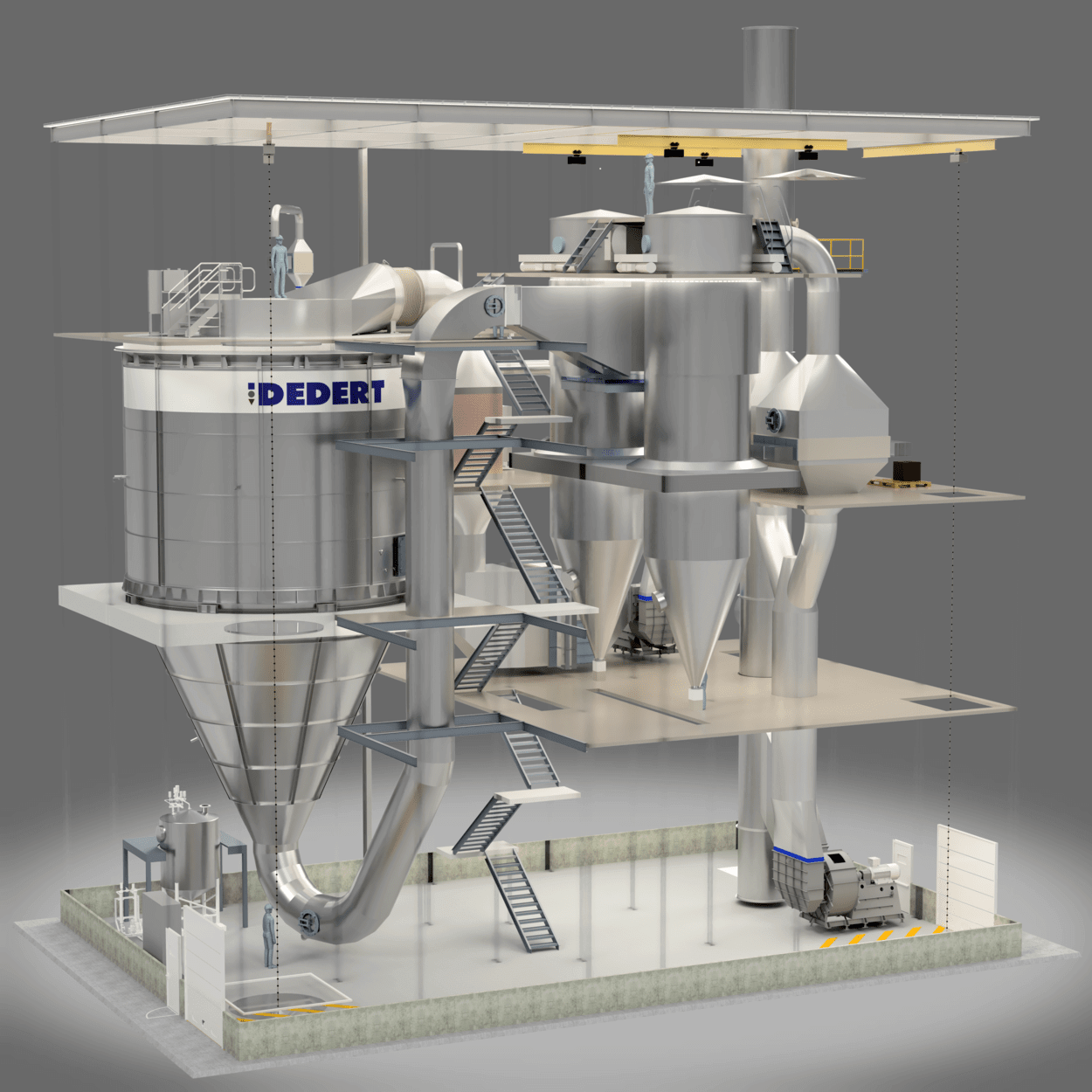

A single-stage spray dryer is used to dry lithium-based feeds.

Single-stage spray dryer with rotary atomizer

Single-stage spray dryer with nozzle atomization

Dedert has two different atomizing systems that are used inside of the spray dryer depending on the customer’s needs:

Both atomizers can produce very small particles, which are necessary to produce LFP batteries.

The ABA is an oil-free and contact-free technology that runs on “instrument” air to achieve atomization.

8 Nozzle AAPN

Air Bearing Atomizer (ABA)

Dedert also developed a new and unique dual fluid pressure nozzle (AAPN) for fine powder applications. This is a high-capacity nozzle which can produce exceptionally fine atomization and small particle size distribution. To produce high energy density in lithium batteries, fine atomization and small particle size distribution are both required.

Spray drying requires high energy usage, and Dedert understands energy efficiency concerns when it comes to spray drying lithium-based feeds. As such, Dedert incorporates energy optimization and integration as part of our drying solution. One example is the use of waste heat and flue gases from other parts of the drying process. Another example is exhaust heat energy recovery.

LFP Spray Dryer for Lithium (Front View)

LFP Spray Dryer for Lithium (Back View)

©2024 Dedert Corporation. All Rights Reserved.