The demand for alternative proteins has never been greater, driving the development of new technology solutions to manufacture innovative proteins and ingredients. The main drivers behind this growth include:

The plant-based protein market, with the key geographic regions of North America, Asia-Pacific, and Europe, is poised for significant growth over the next 3-5 years. To illustrate this growth, here are some key facts:

Historically, plant-based proteins have been produced for animal feed as a low-value by-product of starch or alcohol manufacturing. With the rising demand for alternative proteins, manufacturers have ventured to create high-value proteins aimed for human consumption. Depending on their traditional focus, each type of manufacturer offers a different expertise to plant-based ingredients:

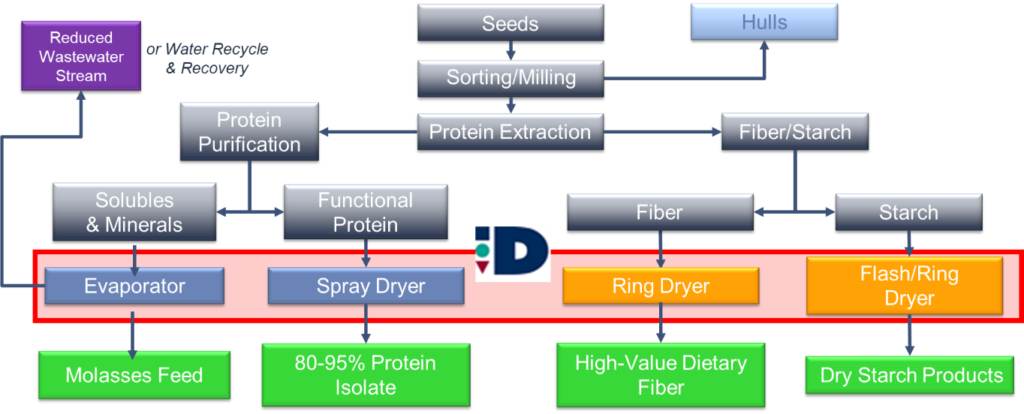

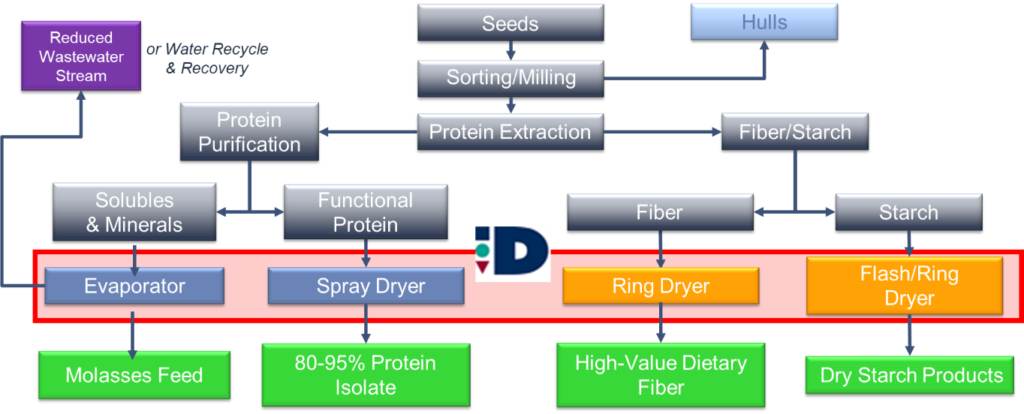

Starch: Manufacturers of various types of starches and sweeteners, including corn wet milling, wheat milling, and other cereal or vegetable processors, are experienced with fractionating crops into the starch, protein, and fiber (and oil in oilseed applications). This expertise translates very well to plant-based proteins by adding a protein purification process. Starch manufacturers can successfully integrate a wet fractionation process into their operations or develop new facilities for manufacturing high-grade protein isolates (85%-95%) and co-product ingredients (fiber & starch).

Agricultural Commodities: Processors of commodity grains have strong experience in bulk grain storage and handling, including milling and blending into specialty flours. To further diversify the product offering to include high-value proteins, this expertise can be integrated into the front-end of a dry fractionation process. These CAPEX-limited projects generally feature air classification methods for fractionation, but have a limited protein concentration capacity suitable for targeting the protein concentrates market (55%-65%). Through some technology innovations, slightly higher protein concentrations are possible. Alternatively, manufacturers can invest additional CAPEX for a wet fractionation process to directly access the higher-value protein isolate market with technical support from experienced partners.

Brewery & Alcohol: Manufacturers of fuel ethanol have been diversifying their products for over 10 years, varying the alcohol grades for new applications and refining the by-product distillers’ dried grains and solubles (DDGS) into a co-product Hi-Protein DDG. These innovations have allowed companies to emerge as Specialty Products manufacturers, including ingredients for feed, food, personal care, and more. In parallel, brewing companies have expanded into the specialty products market by extracting added-value from their waste streams from beer-making, including specialized proteins and feed from spent yeast and spent grains. Both domains offer unique expertise in fermentation technologies, and some manufacturers have started partnering with start-ups who have specialized proprietary protein-extraction processes to support commercialization projects.

Established manufacturers with existing large-scale processing operations are currently financing or investing in initiatives in plant-based product innovations and process developments. These initiatives include investment support for commercialization studies, installation of self-contained Pilot Plant facilities for R&D testing purposes, or full-scale demonstration plants.

The current challenges to overcome in determining the level-of-involvement or the project criteria are rooted in the relative infancy but rapid evolution of the industry. Given the consensus that plant-based foods are poised to make a significant impact on the world’s food supply, why are new ingredients-manufacturing projects facing cautious optimism?

To help navigate these challenges and support the development of ingredients projects, strategic partnerships between process/equipment suppliers (while integrating the customers into the process) would be beneficial in de-risking the opportunities. These inter-vendor partnerships would offer projects a guiding-hand from project genesis to process development, and ultimately through successful execution. This approach is characterized by consultative engineering, R&D, testing, pilot plant validation, and collaborative process design of complete systems from A-to-Z. From grain-handling to milling to processing to packaging. Particular focus for this developing market is placed on new product innovation and product development, which requires flexible Pilot Plant capabilities, as well as testing equipment suitable for scaling-up the process to industrial and commercial size.

For a given process manufacturing system, Dedert Corporation can be an ideal partner to integrate evaporation and drying technologies such as Spray Drying of protein, Ring Drying of fiber, Flash Drying of starch, and Evaporation (concentration) of solubles. Equipment designs are customized and scaled-up through R&D from our in-house Pilot Plant facilities based on product development, process innovation, and operational optimization.

The plant-based protein market is evolving faster than we think. Advancements in manufacturing processes and the involvement of experienced manufacturers with complementary expertise are critical to keeping-up with this evolution. However, challenges in developing new projects remain prevalent in the rapidly growing environment and require technical solutions from innovative companies partnering towards successful implementation of new manufacturing facilities. Strategic partnerships between manufacturers, process providers, and equipment suppliers is important to successfully implement a holistic approach to optimize a process design with a seamlessly integrated process solution. This approach opens opportunities to lower the cost of operations and therefore provide easier access-to-market for new product innovations that meet changing customer expectations in a growing industry.

©2024 Dedert Corporation. All Rights Reserved.