Silica Drying Technologies: Strengths and Challenges

Silicon dioxide (silica) is an oxide of silicon with the chemical formula SiO2, most known in nature as quartz. It is one of the most abundant minerals present on earth and makes up more than 10% of the earth’s crust. Silica is the major constituent of sand in many parts of the world. It is used in structural materials, microelectronics as an electrical insulator, and in the food, pharmaceutical, and construction industries. Some of the most used applications for synthetic silica are toothpaste and car tires.

However, synthetic silica is used in a wide variety of industries and is formulated in numerous ways for both industrial and consumer applications.

In this article, we’ll talk about:

Types of Silica and Their Usage

1. Precipitated Amorphous Silica

Precipitated amorphous silicas are widely used in a variety of synthetic rubber applications including tires, footwear, technical rubber and silicone rubber. They are effective in rubber formulations to add tear strength, abrasion resistance, and aging resistance.

2. Amorphous Silica

Amorphous silicas are used as a matting agent for wood coatings, roofing, ceiling, and siding of your home.

3. Colloidal Silica

Colloidal silicas are ideal inorganic binders and strengtheners and are used to create gloss on the topcoat of a range of ink types including water-based dyes and pigmented, solvent-based, eco-solvent, and oil-based inks. These silicas can also be applied as a clear surface treatment on paper and linerboard products, resulting in a surface that has improved antiskid and anti-slip properties.

4. Micronized Silica

Micronized silicas are used for refining and processing of edible oils and fats to help improve quality and stability, and to also reduce neutral oil losses. They remove naturally contained and process-induced contaminants such as soaps, phospholipids, and trace metals to ensure food safety. Micronized silicas are also used within the cosmetic industry. Micronized silica particles act as anti-caking and free-flowing agents which help to prevent clumping and caking during processing and storage.

5. Hydrogel Silica

Hydrogel silica is an amorphous, non-crystalline, high-quality gel that is used as a beer stabilizer. This is a highly pure and consistent protein adsorbent that was developed specifically for the brewing process to extend the shelf life of beer without impacting foam and flavor stability.

What special properties does silica have for drying?

Generally, silicas have very small particles that are easy to dry. Their particles do not adhere or bind to each other easily. Silicas can be engineered to have very specific properties, thus making them useful for a variety of applications within many industries.

Advanced Drying Technologies for Silica by Dedert

Dedert provides three innovative drying solutions tailored for silica:

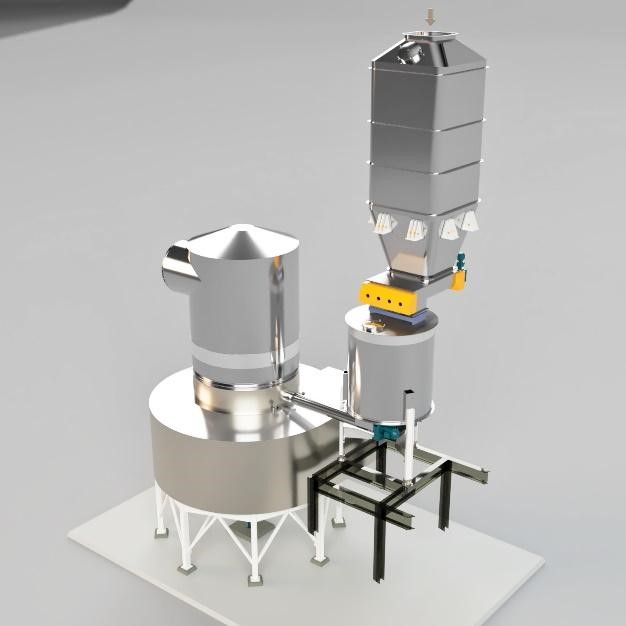

- Roto-Flash Dryer: An agitated flash dryer, adept at transforming wet feed material into fine powder within seconds, making it economically efficient.

- Spray Dryer: Primarily used in the food and chemical domains, this dryer turns liquid feed into fine powder, with a particular emphasis on drying silica.

- Ring Dryer: A versatile industrial dryer that stands out due to its "manifold classifier." It's ideal for drying a wide range of materials, especially silica, and offers additional milling benefits in the airstream.

What is Dedert’s Roto-Flash Dryer and What Does It Dry?

Dedert’s Roto-Flash dryer is an agitated flash dryer. The drying takes place in a cylindrical vertically mounted drying chamber. The rotor-beater assembly provides sufficient force to disperse and break down the wet feed material for drying. The process results in a very fine powder directly from the wet feed material, without the need to pre-mix with already dried product.

The air residence time is only a few seconds, making the Roto-Flash dryer cost effective both in terms of capital expenditure and operating costs.

Dedert’s Roto-Flash feeds cakes/pastes, producing a fine powder with a uniform moisture content and consistent particle size distribution. This dryer typically dries inorganic chemicals such as silica.

What is The Advantage of The Roto-Flash Dryer as It Relates To Particle Size, Bulk Density, etc.?

The Roto-Flash dryer is a high heat transfer system that can do effective drying with a small footprint. One of the main advantages of the Roto-Flash dryer is that it offers milling. The Roto-Flash can break down agglomerates and create very fine particles. As the product dries, it recirculates through the beaters and can break down into small, uniform particles. This is beneficial for the use of silica to produce a fine particle size distribution used in coatings.

The Roto-Flash can also dry thicker and pastier materials like wet cakes and slurries. Bulk density is typically higher than what would be obtained by spray drying.

What is a Spray Dryer and What Does It Dry?

The single-stage spray dryer is the most common and most flexible solution for drying a full range of products for the food and chemical industries. The liquid feed is dried to a fine powder in the drying chamber and discharged from the cone bottom or conveyed with the exhaust air to a primary separator, either cyclones or a dust filter.

When drying silica, the most frequently used type of spray dryer is the single-stage co-current dryer with the rotary atomizer or nozzle atomizer.

What is a Ring Dryer and What Does It Dry?

Ring dryers, also known as pneumatic dryers, are a type of industrial drying equipment that dries a variety of materials. They have a unique feature that sets them apart from typical flash dryers: a “manifold classifier” positioned in the drying system. They are most used within the food, chemical, and pharmaceutical industries to remove moisture from wet materials by applying heat, causing the moisture to evaporate.

When drying silica, it is most common to use the full-ring dryer. The full-ring dryer features a unique manifold design that offers two functions: solids recycle through the hot duct to the air-swept disintegrator; and extended residence time, if necessary, within the manifold to achieve sufficient dryness. This dryer type is particularly useful for challenging drying applications that require extra milling in the airstream.

How Does The Spray Dryer Compare to The Roto-Flash and Ring Dryer?

Spray dried powders are typically larger than what is obtained by the Roto-Flash or ring dryer. Thus, spray dried powders will feature a free-flowing powder due to the particle size, which can be several times larger than what is obtained in the Roto-Flash dryer. The spray dryer feed material must be pumpable and be able to atomize, a requirement not needed for the Roto-Flash nor the ring dryer.

Therefore, operating costs (OPEX) for the spray dryer are higher as more water in the feed is required to make the feed material both pumpable and able to atomize. The spray dryer also produces powders that are less dusty, which is important for reducing potential health risks associated with excess dust post-drying.

Are There Specific End Uses Which Determine The Dryer Type For Silica?

Not necessarily, but Dedert can supply whichever technology our customers want for their specific drying needs. In most cases, the customer will determine which technology they want to purchase with the help of Dedert’s experienced engineers’ suggestions and the use of our testing facility.

Typically, pigment-based silica used in paint products needs small particles which are spheres that result in high gloss coverage paint. Dedert offers multiple technologies to suit this need, including the spray dryer and the Roto-Flash dryer which both produce fine powders with small, uniform particles. Dedert’s Roto-Flash dryer has been used to produce silica that is formulated into toothpaste, where it acts as an abrasive.

What are The Differences Between The Spray Dryer, Roto-Flash Dryer, and Ring Dryer When Drying Silica?

Strengths

Challenges

How will the particle requirements determine the type of technology to use?

If the customer’s objective is to dry any type of product size, then Dedert’s Roto-Flash dryer or ring dryer could be used. Once the product is dried, the use of post-milling might be needed to create a much finer powder. For many inorganic products featuring little inter-particle strength, the Roto-Flash dryer will produce a powder with the same primary particle size as is seen in the feed material.

Conclusion

Silica, with its wide range of applications and unique properties, remains indispensable in multiple industries. Dedert, through its cutting-edge drying technologies, caters to these requirements, ensuring optimal results tailored to specific industry needs.