When it comes to the protein market, wheat gluten is one of the original food ingredients. Though not as glamorized or promoted as other protein ingredients today, it continues to be a growing commodity in both aquaculture or as a high value baking ingredient (vital wheat gluten).

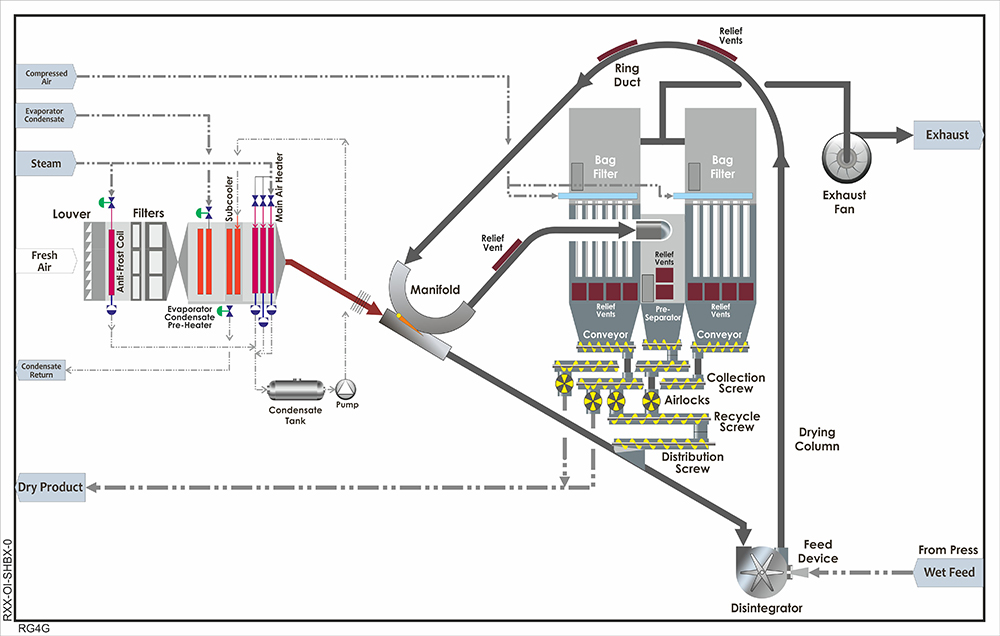

Dewatering, drying and milling of wheat gluten is one of Dedert's most specialized processes. Our team's experience can be traced back to the early 1970s, when one of the first wheat gluten dryers was fabricated. For today's market, automation plays a central role increasing safety, reducing supervision requirements, improving product quality and increasing plant availability. Dedert supplies the full process from the screw press to the full ring dryer to the milling system, producing a quality product with guaranteed vitality and water absorption characteristics.

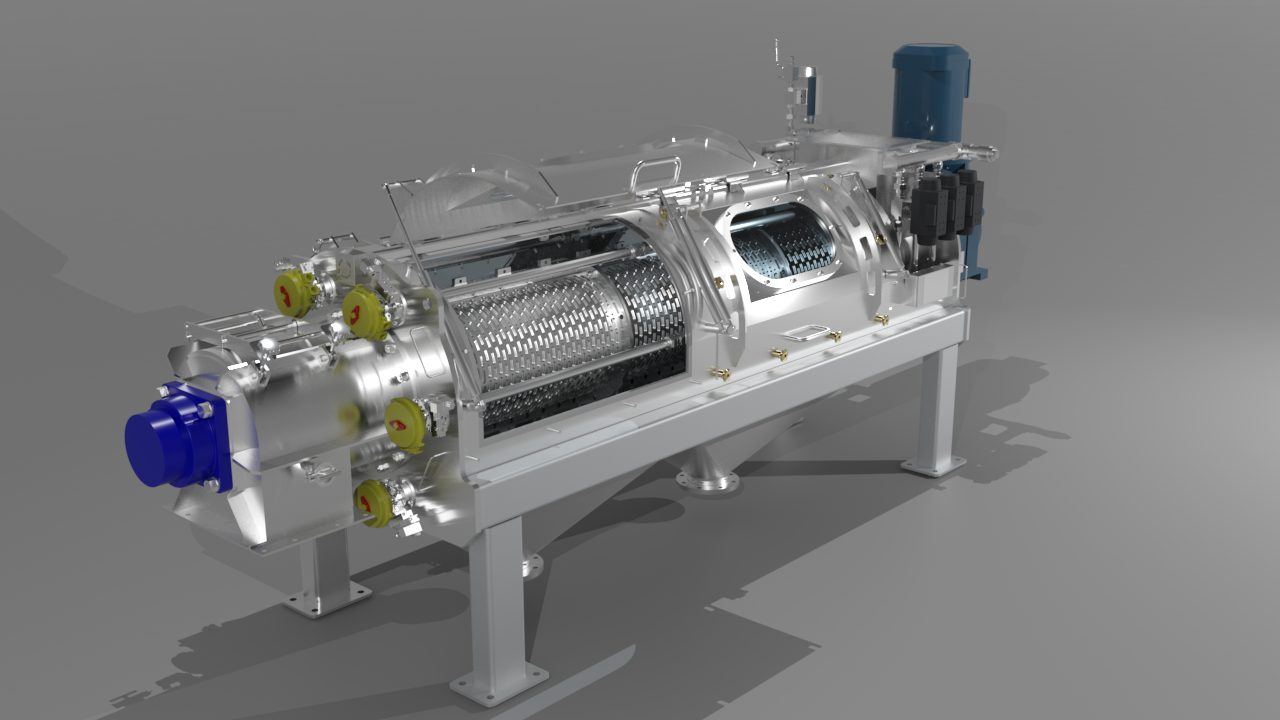

The screw press provides additional dewatering to the wet gluten prior to being pumped to the dryer, significantly improving the overall energy efficiency of the system. The integrated hopper receives the wet feed from the upstream process before it is compressed in the conical screw. Dedert provides an additional screen between the press and the feed pump to further drain any excess filtrate, which can be sent back to the wet processing line.

Traditional screw presses have required manual cleaning of the system every few hours. Dedert's Automated CIP System eliminates this and allows the operator to clean the Screw Press from the comfort of the control room. The spray nozzles are designed with an overlapping pattern to ensure no spot is left unclean. Dedert's screen is also designed with a special pattern which are easier to clean and less likely to trap gluten and starch laden filtrate.

The fishtail feeder integrated into the side of the hot disintegrator, spreads the compressed wheat gluten across its width for an even distribution. Dedert's fishtail design includes a removable tip which can be easily replaced when worn or to adjust the dye gap. In the ring dryer, the manifold classifier is set to recirculate semi-dried solids around the ring, which serves to condition the wet gluten. Our proven manifold design is trouble free and can be supplied with remote actuation allowing for adjustments of the blade from the control room. This gives the operator control of the classifying during operation without the need for manual intervention.

The fishtail feeder integrated into the side of the hot disintegrator, spreads the compressed wheat gluten across its width for an even distribution. Dedert's fishtail design includes a removable tip which can be easily replaced when worn or to adjust the dye gap. In the ring dryer, the manifold classifier is set to recirculate semi-dried solids around the ring, which serves to condition the wet gluten. Our proven manifold design is trouble free and can be supplied with remote actuation allowing for adjustments of the blade from the control room. This gives the operator control of the classifying during operation without the need for manual intervention.

A safe minimum humidity is maintained in the dryer preventing an overly dry environment from developing in the bag filter. During normal operation, water evaporation from the wet gluten is enough to maintain safe humidity levels in the dryer, however this is not the case during start-up, shutdown, upset conditions and turn down operation during which times the addition of steam is required. To minimize steam consumption and save on utility costs, humid dryer exhaust air is recirculated back to the inlet of the dryer, which is a fully automatic function constantly monitored and adjusted by our well defined control system.

Dedert's wheat gluten milling system utilizes the best-in-class air classifying milling technology to provide control of particle size distribution and strict maximum particle size guarantees to our customers. Furthermore, Dedert's expertise in pneumatic systems provide a clever use of fan placement which prevents conveying line blockages during overfeeding events and reduces required fan installed power.

In addition to the above, Dedert's in house design of other key components, such as the hot disintegrator and bag filter with integrated preseparator are an integral part of wheat gluten dewatering, drying and milling technology.

For more information, please contact a Dedert representative.

The fishtail feeder integrated into the side of the hot disintegrator, spreads the compressed wheat gluten across its width for an even distribution. Dedert's fishtail design includes a removable tip which can be easily replaced when worn or to adjust the dye gap. In the ring dryer, the manifold classifier is set to recirculate semi-dried solids around the ring, which serves to condition the wet gluten. Our proven manifold design is trouble free and can be supplied with remote actuation allowing for adjustments of the blade from the control room. This gives the operator control of the classifying during operation without the need for manual intervention.

The fishtail feeder integrated into the side of the hot disintegrator, spreads the compressed wheat gluten across its width for an even distribution. Dedert's fishtail design includes a removable tip which can be easily replaced when worn or to adjust the dye gap. In the ring dryer, the manifold classifier is set to recirculate semi-dried solids around the ring, which serves to condition the wet gluten. Our proven manifold design is trouble free and can be supplied with remote actuation allowing for adjustments of the blade from the control room. This gives the operator control of the classifying during operation without the need for manual intervention.