For over 50 years, Dedert has partnered with all the major corn wet milling companies to develop custom-engineered process technologies including evaporation and drying based on consultative engineering, R&D, product testing, pilot plant validation, and process design. From this long experience with the corn wet milling process through these partnerships, Dedert has established solutions for corn germ, corn gluten meal, corn gluten feed (fiber with steepwater), and corn starch.

Drying corn starch requires important experience and process knowledge to maintain the specific functionality and properties for various starch products and end-use applications. Corn starch is dried in an Open-Circuit (OC) configuration, either on a flash dryer or a ring dryer depending on the application.

An OC configuration ensures a high-quality starch product in part due to the low temperature environment. Using ambient fresh air in a once-through arrangement, the product always remains in contact with a clean, unadulterated, low-humidity drying medium to prevent risk of contamination or changes to the product's desired state. Additionally, an indirect heat source like steam-heating avoids product-contact with combustion products. As a result, the dryer configuration prevents discoloration and unwanted denaturation, such as starch gelatinization.

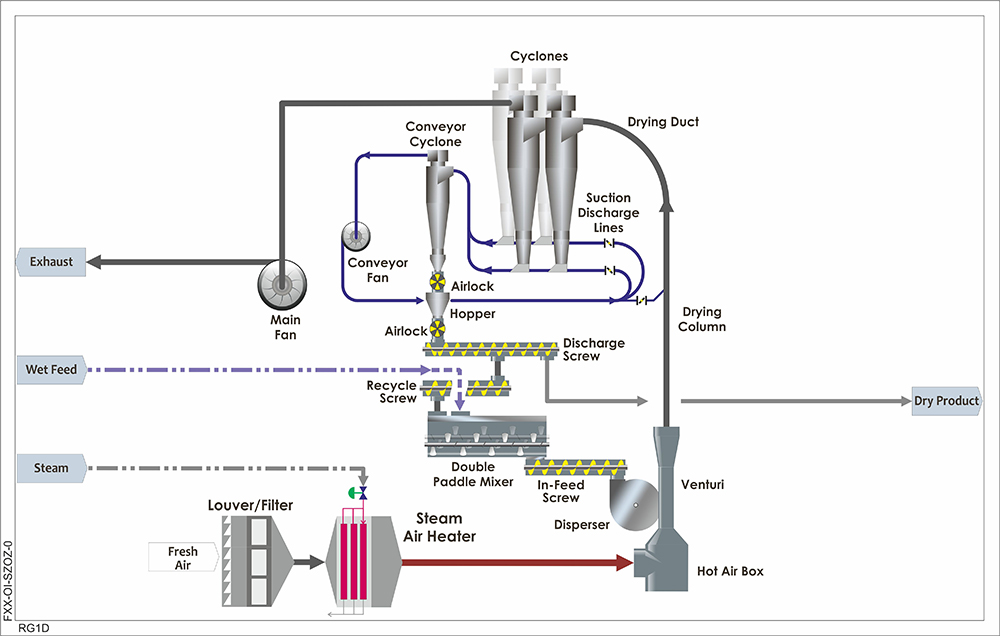

Native corn starch dries easily, so a flash dryer is the simplest and most ideal solution. Flash dryers are pneumatic systems combining simultaneous air conveying and drying, where solids are introduced at the feed point and dry in a 1-pass arrangement before full discharge to the product collection system. With a short residence time of only a few seconds, the solids are in contact with a relatively low heat environment for a short period. A challenge with corn starch is its sensitivity to thermal and mechanical work, so Dedert's flash drying system is attentive to temperature profiles, feed conditioning, and gentle dispersion into the drying airstream. The system design also considers the highly combustible nature of corn starch; Dedert's robust design and use of re-closable vent doors ensures personnel safety and easy operation in deflagration events.

A P-Type Ring Dryer, named after its distinguishable "P" shape, is required for Modified Corn Starch to extend the drying time for the removal of bound or interstitial moisture. Ring drying is an extension to flash drying with the addition of a manifold classifier to allow semi-dry solids to internally circulate until fully dry. The P-Type manifold directs the solids recycle back into the lower-temperature exhaust zone for temperature-sensitive corn starch. Nonetheless, residence time remains short, still on the order of a few seconds, so the solids are not exposed to a high-heat environment for a long duration. The ring dryer configuration also enables the dryer to be more energy-efficient relative to a flash dryer designed for the same application.

Connect with us to discuss your pea protein and co-products applications, or other plant-based ingredient processing requirements!